EPS Bonded Bead Cavity Wall Insulation

We install insulation into your cavity walls with market leading EPS Bonded Beads.

More heat is lost through the walls of your home than in any other way. By investing in cavity wall insulation you can significantly reduce the heat loss from your home. Maintaining the heat inside your home keeps you warm and cosy and reduces energy use and can eliminate condensation issues your home may have.

Installing cavity wall insulation in your home will not only help to decrease your heating bills by saving energy lost through the walls, it will also help to reduce your carbon footprint by limiting the amount of CO² and other greenhouse gases emitted from your property.

Features of bead cavity wall insulation

-

- The safest and most effecient cavity wall insulation

- The ideal solution for hard to treat properties

- A lambda value of just 0.033

- 20% more efficient than blown fibres and wool

- 30% less drill holes when compared to other insulations

- BBA and BDA or KIWA approved for 40mm cavity widths

Benefits of cavity wall insulation

-

- Cost effective – payback time as low as 2 years to 5 years

- Up to 30% reduction on fuel bills

- Provides high level of thermal efficiency

- Reduces heat loss by around 70%

- Reduces condensation and black mould growth

- High exposure area approval

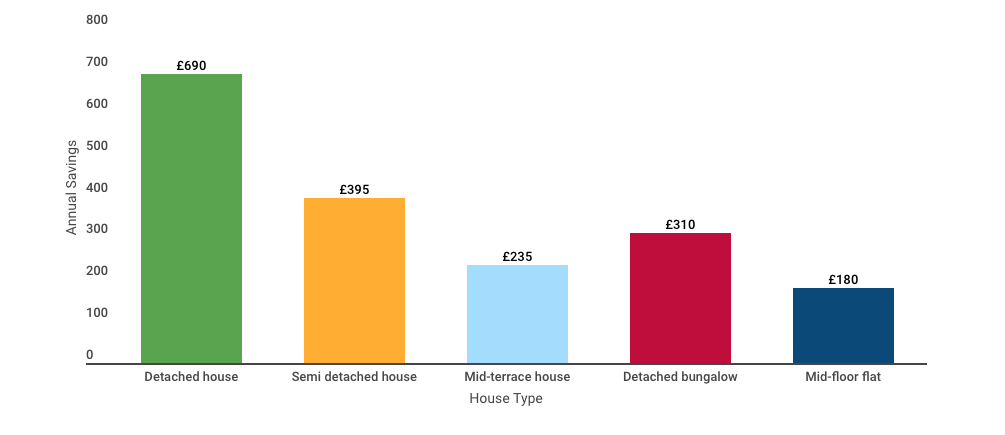

Energy Bill Savings From Cavity Wall Insulation

The below estimates of typcial savings are provided by the Energy Saving Trust

These have been based on gas heated homes with fuel prices as of October 2022.

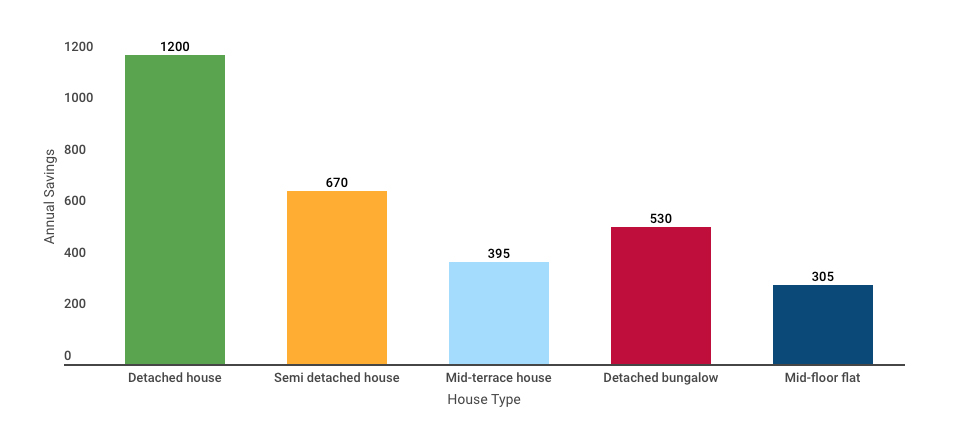

The below estimates are provided by the Energy Saving Trust

show the typical Carbon Dioxide savings (kgCO2/year)

About Cavity Wall Insulation

25 year insurance backed guarantees for insulation installs on domestic properties

Many houses since 1900’s were built with a cavity between the inner and outer walls. Due to this cavity, many of Britain’s homes have thermal performances which are well below the standards required by current building regulations, with unacceptably high levels of heat and energy loss through the walls.

Cavity wall insulation is suitable for houses which have a cavity space of at least 40mm between the two brick/block walls. Unfortunately timber framed, steel framed, random stone and solid wall properties are not suitable for cavity wall insulation. However, they may be suitable for our external wall insulation.

The EPS Bonded Bead product is an innovative cavity wall insulation material that provides an extremely high level of thermal wall efficiency. The system is both BBA and KIWA certified and has quickly gained a reputation throughout the UK as the best and most trusted insulation systems yet seen for cavity wall installations.

EPS bonded bead insulation is ideal for domestic, commercial and industrial use. Due to the drill pattern, air pressure and the nature of the bead we can provide 100% cavity fill with no cold spots, no waste and easy to install. EPS has outstanding durability, it is water resistant and wont break down until it is recycled again.

Additional Details of Cavity Wall Insulation

-

- The bead is installed through holes drilled into the wall (hence cavity wall insulation). On existing properties the holes will be drilled through the external wall. On new build the holes could be drilled through the inside wall, prior to plastering or plasterboard.

- The blown bead cavity wall insulation is extremely effective in both new build and existing properties.

- Blown bead offers a proven 100% cavity fill, ensures no cold spots, gives fully guaranteed insulation and eliminates the need for bricklayers to install fitting boards – a time consuming process that can add as much 12% extra time spent on a build.

- Blown beads in situ will not allow water to cross the wall construction. The beads themselves allow the safe dispersal of any water. The gaps that naturally occur between the spherical beads allow any water to drain down freely to the ground, rather than across to create damp problems on inside walls.

- The structure of the installed blown bead allows the cavity to retain the ability to breathe as intended with the cavity wall insulation in place.

-

- Outstanding durability – blown beads are rot proof, water resistant and sufficiently stable to remain effective as an insulation for the life of the building.

- No settlement – as the blown beads are coated with an air drying bonding agent during installation. There is no possibility of settlement occurring. The insulation remains in place for the life of the building ensuring that it is not possible to create gaps at the top of the property.

- A consistent density of insulation

- Constant thermal projection throughout the installed area.No wastage – the beads flow unrestricted, totally filling the cavity, forming a homogeneous heat saving mass.A straightforward installation process that is time efficient and has a low H&SE liability.

- Zero ODP (Ozone Depletion Potential)

- Low GWP, less than 5 (Global Warming Potential)

- CFC, HFC and HCFC free

- No wastage on site

- Green guide summary 'A' rating

- 100% recyclable

Frequently Asked Questions of Cavity Wall Insulation

Cavity bead and the Environment

EPS cavity wall insulation is the reassuringly familiar EPS (expanded polystyrene) bead. EPS has outstanding insulating properties and is currently used in many different forms in the construction sector.

Selecting Evobead is a good choice for the environment because:

- The BRE Green Guide to Specification awards EPS an A+ summary rating in its insulation section

- EPS bead has a low GWP (global warming potential)

- EPS bead has zero ODP (ozone depletion potential)

- No CFC’s and HCFCs are used in the manufacture of Evobead

- EPS bead is 98% air making it resource efficient and a great insulator

- EPS bead is an inert material that does not deteriorate over time

- EPS bead is unaffected by moisture and is not damaged by uncontaminated flood water or rain water

- EPS bead is non toxic

- EPS bead is 100% recyclable and thousands of tonnes of EPS packaging are recycled every year in the UK

- Evobead is made with InVento – the newest Synthos EPS product line created specifically for taking care of the natural environment.

- Evobead is a premium class grey expandable polystyrene (EPS). Evobead is innovative and ecological designed for a wide variety of applications on the thermal insulation market such as cavity wall insulation. The heat transfer coefficient λ reaches values below 0.033 W/m·K.

- InVento is manufactured using a state-of-the-art production line, the only one of its kind in the world. The InVento production process uses a unique, ecological Geopolymer additive which acts as an athermal substance.

- The special feature of the InVento product line is its ecological character which is compliant with the principles of the Circular Economy.

- The huge competitive advantages of the InVento family are not only thermal insulation parameters of the products but also their ability to be fully recycled as well as a waste-free production process using recycled raw materials. The excellent processability of InVento allows reducing material losses and gives the possibility of reducing processing times resulting in savings.